Why food coating flexibility is trending right now

As a result of an increasing trend for home dining and takeaways, convenience food is in higher demand than ever before. On the producer side, countless market research surveys confirm a global demand for higher capacities and more variety in ready meals. The modular coating lines from alco, which can be arranged and rearranged according to each individual product, are the best solution for any need for high-volume, high-quality products with flexible, cost-saving product changeover.

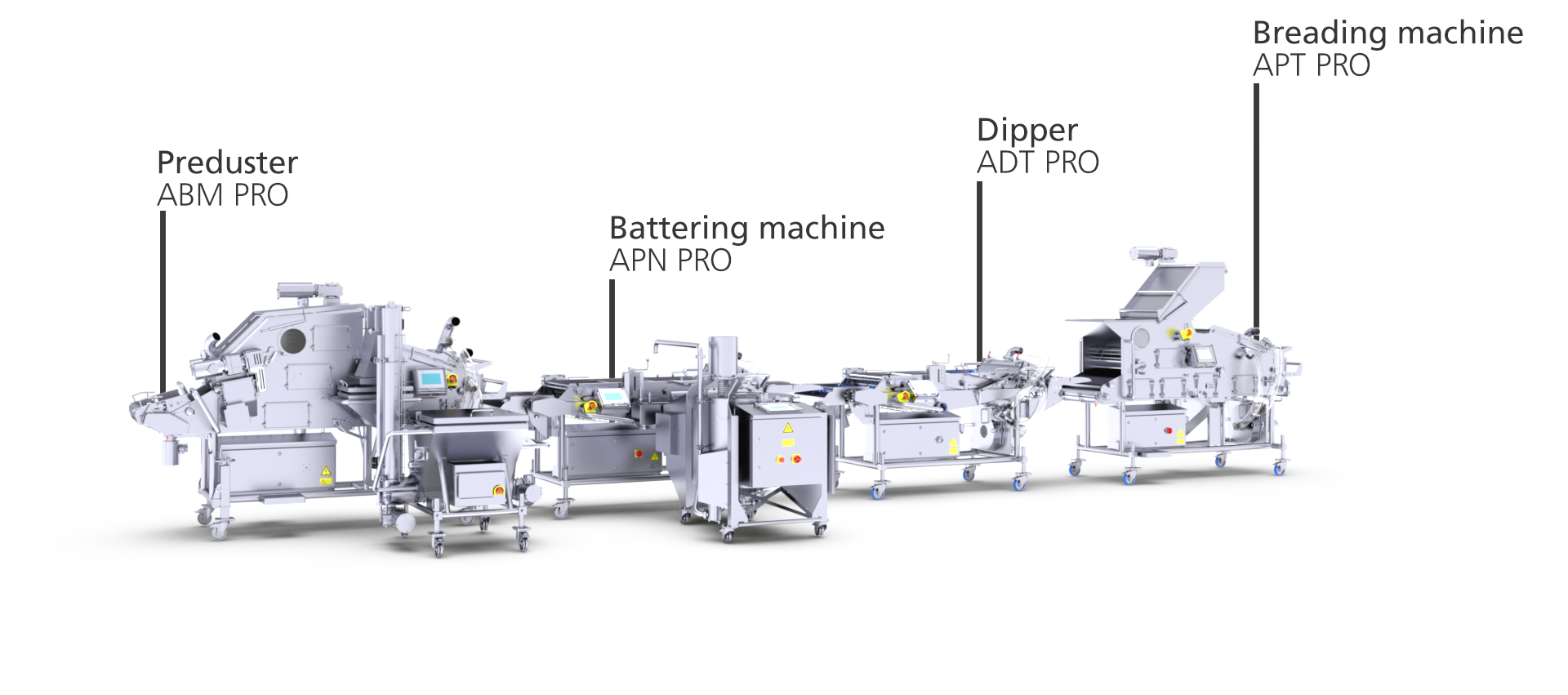

Flexible alco Coating Line PRO Series

More product variety, more product quantity, and rapid switching from one product type to another — these demands only serve to underline the fact that convenience food processors are now facing more pressure than ever to provide greater production flexibility. Since consumers prefer to reach for premium convenience foods, finding the ideal coating solutions that could deliver on the promise and meet all standards was difficult for processors. The alco coating line addresses precisely this issue and, with a wide range of coating equipment, offers the possibility to coat many different products in many different ways, whether for homestyle, tempura, coarse or fine breadcrumbs, spices, or flour.

alco Preduster ABM

For some products, predusting is the only coating process applied. This is especially common for products such as fish fillets, fried rings, shrimp, and drumsticks. However, this process is mostly used when difficult or complex products need to be prepared for further coating. Especially for moist products, such as poultry fillets and fish fillets, the flouring often serves as preparation for further coating operations. The same applies to products that have been pre-cooked in steam, such as chicken nuggets. Flouring not only provides an even surface for the subsequent battering, but can also be used to change the character of the product and also serves as a carrier for spices and flavors.

alco Battering machine APN

Battering is typically combined with flouring and/or with fine or coarse breading. The process is most frequently used to apply an adhesive layer for the subsequent breadcrumbs. By using powerful pumps, it is possible to process both thin and thick wet panade. The battering also serves as a carrier for salts, spices, and flavorings.

alco Dipper ADT

The tempura batterings are primarily applied as a finishing coating. They are frequently used in combination with predusting. The process is most commonly used to apply highly viscous batterings, which contain raising agents. Because these special, highly viscous batterings cannot be pumped, the products sit in between an upper and lower belt and are gently guided through a bath of coating media. As a result, the tempura coating can rise and form a loose, appetizing coating.

alco Breading machine APT

Breading is most often used in combination with different kinds of battering. It is usually the final layer in the entire coating process. This is where the final appearance of the products is determined. The breading process has a decisive influence on the saleability of the products. With the alco breading equipment, all "free-flowing" breadcrumbs can be processed. This applies to both fine-grained and coarse-grained breadcrumbs. Even the processing of mixed breadcrumbs and cornflakes is possible without any limitation.

Got any questions? We’d be happy to personally advise you!

You can get more information on the dry breading machine and our food processing machines right from our team. We’d be happy to help you out in making plans, a purchase decision, and maintenance arrangements for your machine.