The Spiral Oven ASH: Roasting efficiently and gently

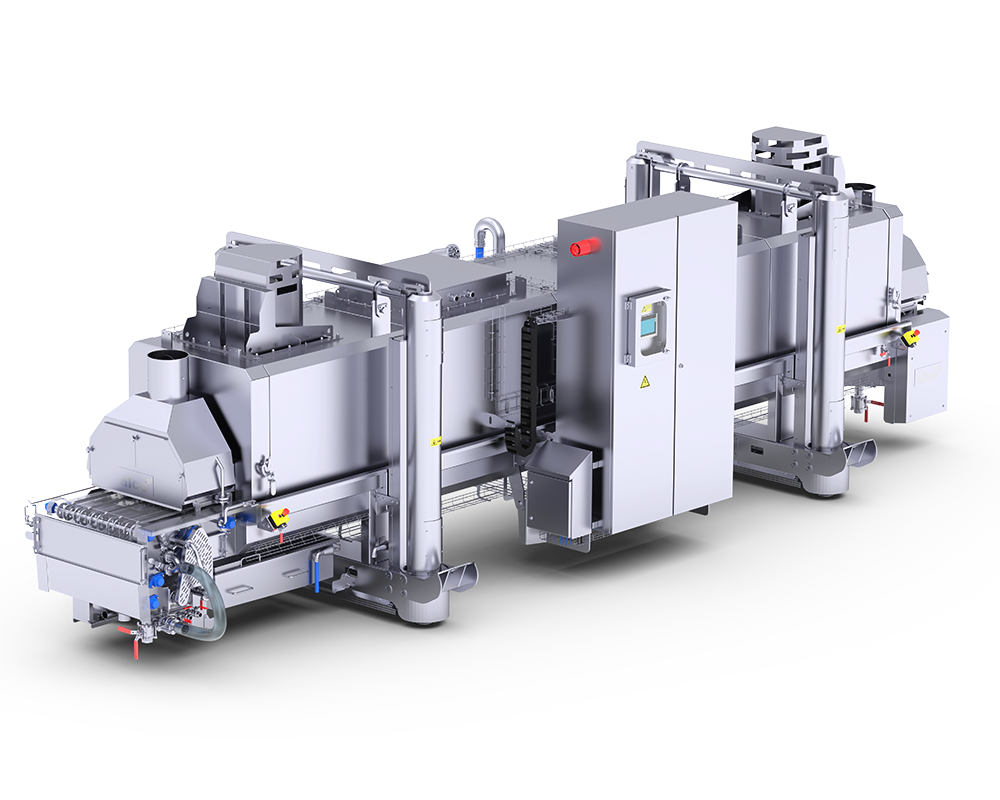

Our spiral oven serves for cooking and/or browning your products with steam, hot circulating air, or both. Its spiral belt guide allows plenty of room in our oven for products, which are cooked in a gentle way.

Function

Cooking, heating, browning: The spiral oven from JBT ALCO slowly and gently runs products through the cooking process by means of a spiral conveyor belt that can be extended if required. That way, large quantities of your product will be cooked, roasted, browned, or just steam-cooked very evenly in the spiral oven with circulating air and/or steam. The smart spiral system makes optimum use of the available space, so that maximum production capacity is achieved in the smallest possible space. At the same time, the distance between the individual levels and therefore the possible product height can be flexibly varied by selecting the number of levels. That way, even larger products such as whole chicken, burgers, or lasagna get their appetizing brownness and succulent consistency.

Features

Our spiral oven heats, cooks, and browns products through circulating air and/or steam. Adjust the spiral belt guide individually to product quantity and size.

Details

- Continuously adjustable production speed

- Suitable for products of various sizes thanks to a selectable amount of levels and thus a variable product height

- Optionally heated electrically or with thermal oil or steam-powered

- Targeted airflow in the system itself guarantees optimal and uniform heat transfer and browning

- Continuously adjustable variable ventilators

- Steam injection bars for setting the desired humidity

- Optional dew point control for maximizing yield

- Process temperature infinitely variable up to max. 230 °C

- Automatic, continuous belt wash system in combination with CIP nozzles in the interior of the oven ensures perfect cleaning

- Intuitive operation through a touch panel with recipe management

- Linked with the remote maintenance service

- Insulated housing design for preventing energy losses

- Made entirely of stainless steel and food-approved plastic

- High operating safety

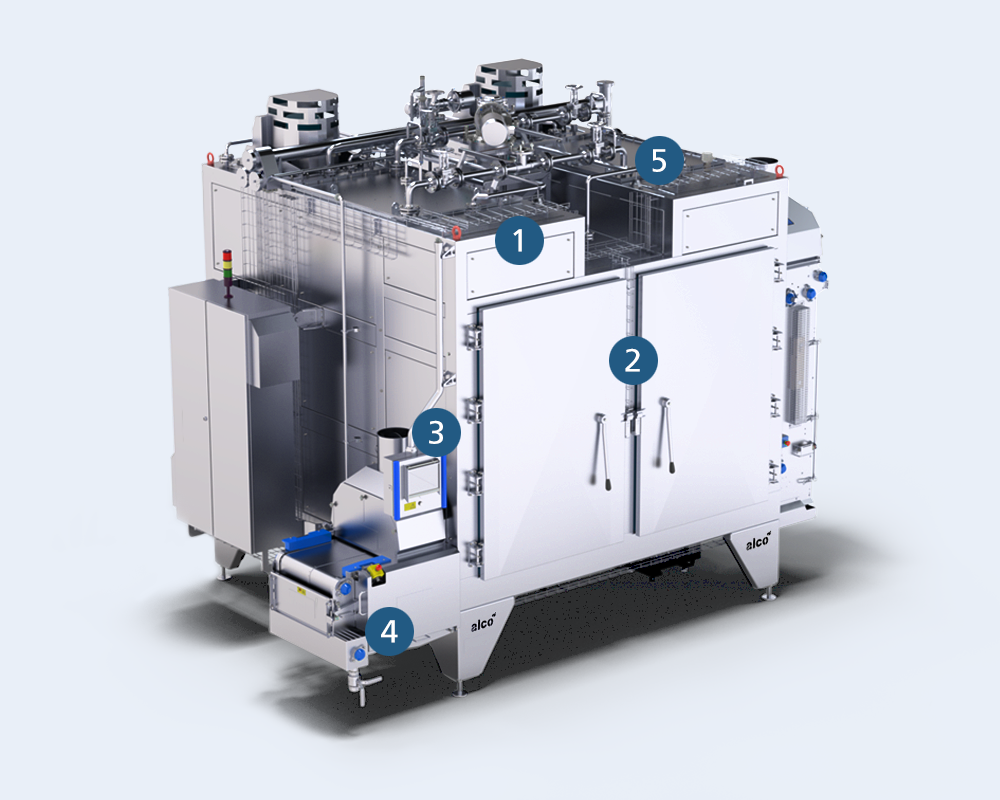

Our spiral oven

1: Top performance heating elements

ensure efficient heat transfer. Choice between electrical and thermal oil and steam-powered heating elements possible.

2: Variable stage belt system

allows for the selection of 5 to 10 levels.

3: PLC control

controls the plant in a smart and user-friendly way through a touch panel with functions like recipe management, etc.

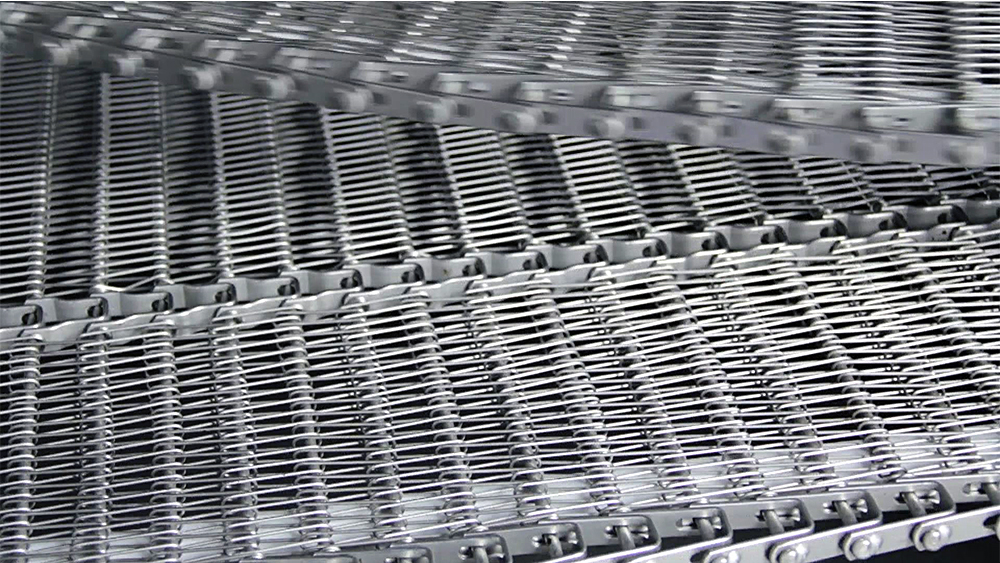

4: Automatic belt wash system

continuously cleans the conveyor belt by means of rotating brushes and water spray lances.

Optional

5: Steam nozzles

additionally heat the product through direct steam injection for lowest weight loss.

Accessories

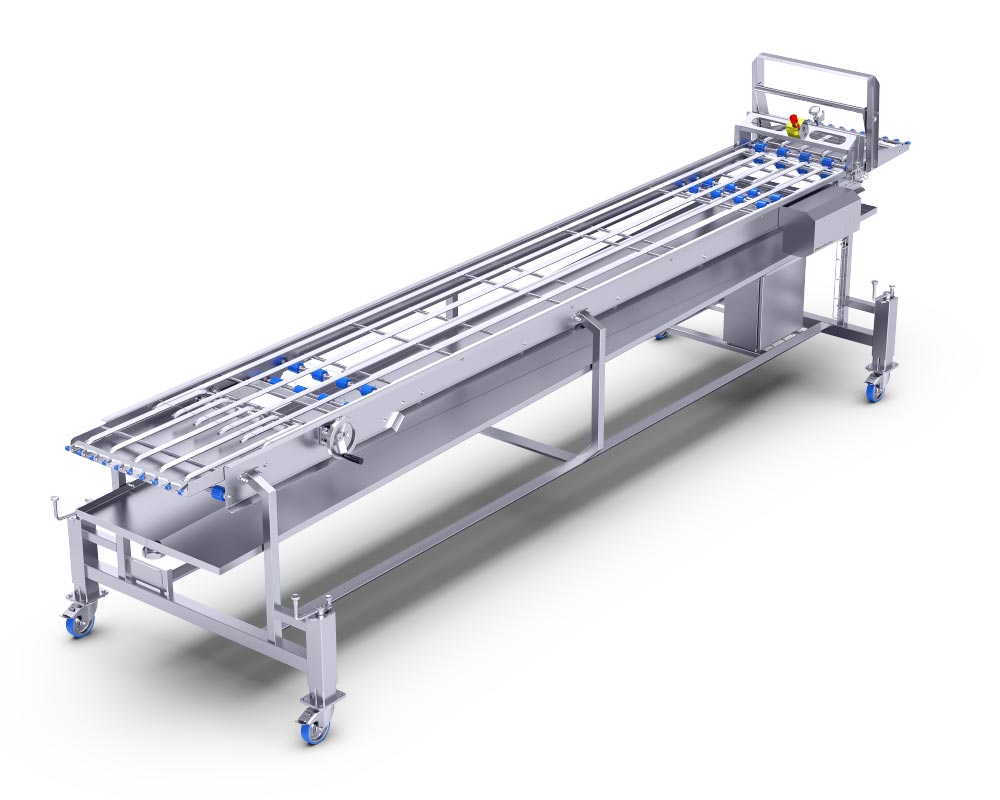

We’ve developed suitable accessories for our spiral oven that facilitate processing and provide additional functions for you. Ask your contact about all machine options and get equipment that’s perfectly tailored to your needs.

Even in front of and behind our spiral oven, you can count on our reliable technology. Our conveyor technology ensures optimal line integration and convenient filling. From different conveyor belts for all requirements to spiral conveyors and lifting and tilting devices to special solutions made just for you, we’ve got the right accessories for your food processing machines.

Got any questions? We’d be happy to personally advise you!

You can get more information on the spiral oven and our food processing machines right from our team. We’d be happy to help you out in making plans, a purchase decision, and maintenance arrangements for your machine.